Hva er 3D-printing?

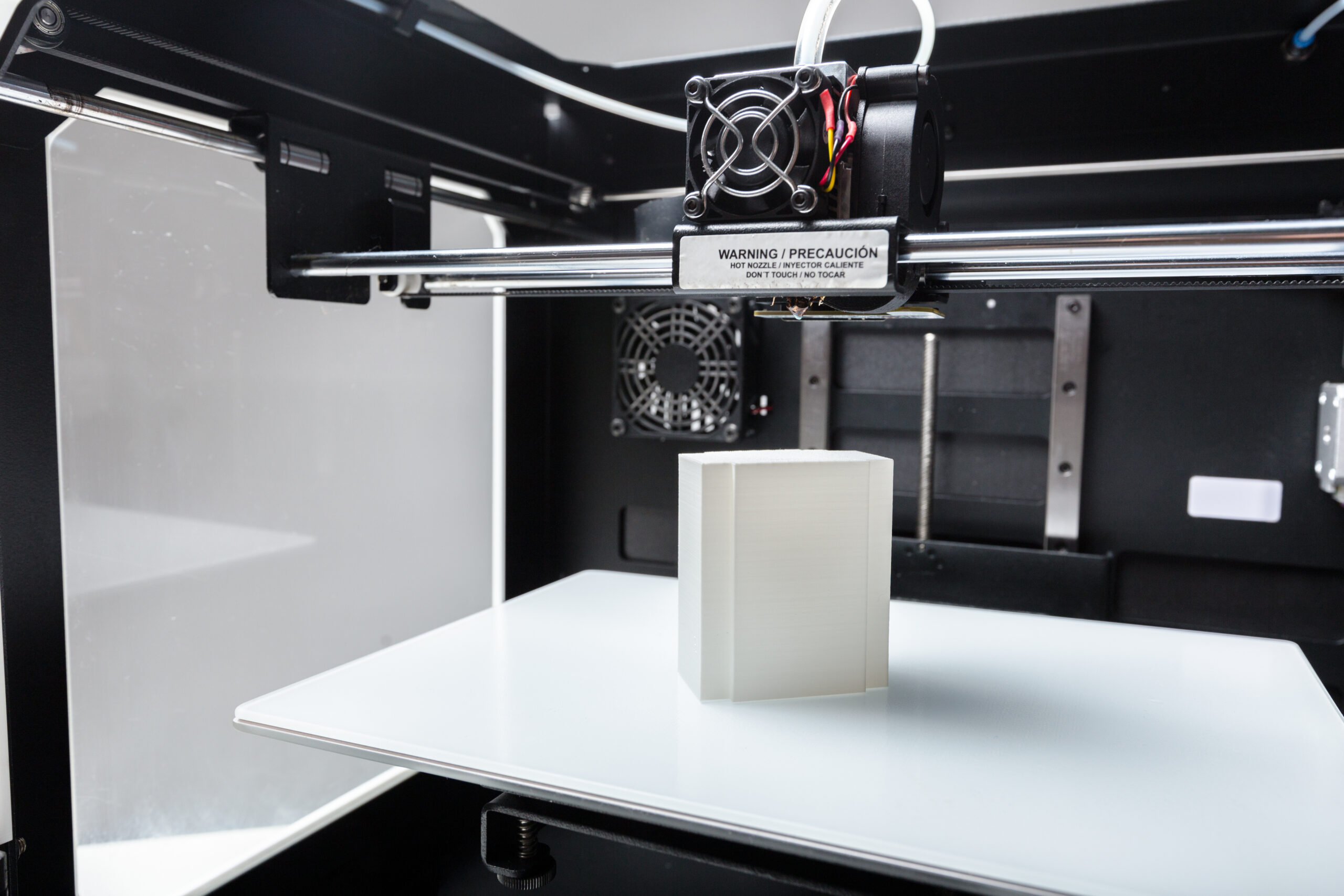

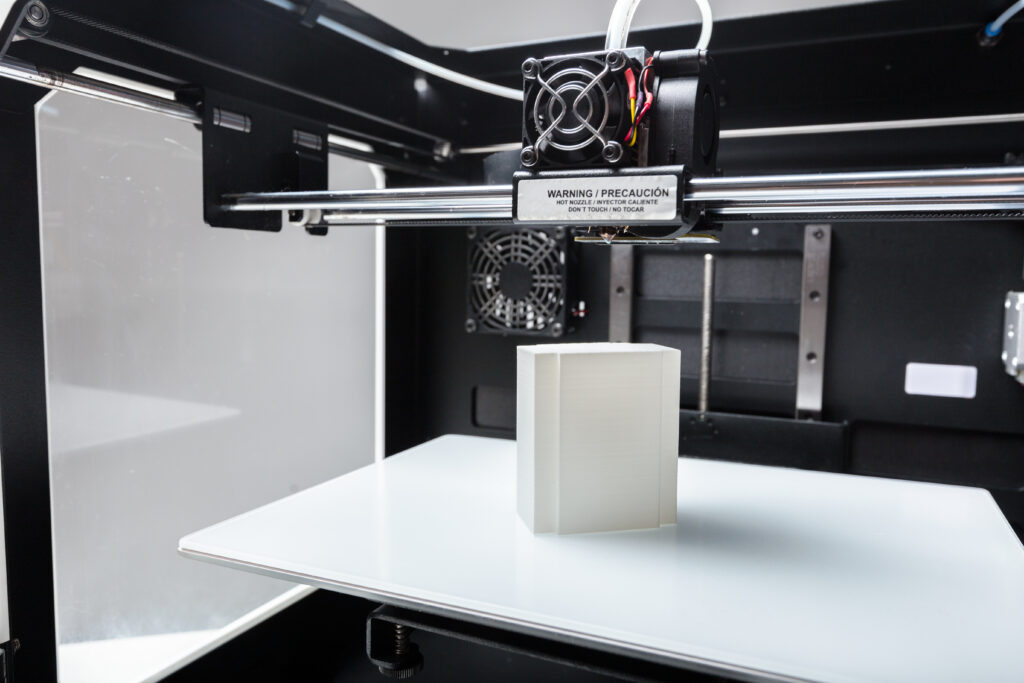

3D Printing eller additiv produksjon, er en prosess for fremstilling av et tredimensjonalt objekt fra en digital 3D modell eller CAD-fil. 3D printing ble først utviklet som en metode for å raskt kunne produsere funksjonelle prototyper og små modeller. Man starter med å designe et 3D -objekt på en datamaskin, laster den opp til 3D-printeren, trykker «skriv ut» og venter. Kjennetegnet til 3D printing er at det er en produksjonsmetode der materialet legges til istedenfor å fjernes.

Hvordan fungerer 3D-printing?

3D -printing er en ny generasjon maskiner som kan lage det meste. De er bemerkelsesverdige fordi de kan produsere forskjellige typer objekter, i forskjellige materialer, alle fra samme maskin. Med 3D -printing kan man lage stort sett alt fra keramiske kopper til plastleker, maskindeler i metall, hus i betong, flotte sjokoladekaker eller til og med kroppsdeler.

Fused filament fabrication (FFF) er den mest brukte metode for 3D-printing. FFF er en prosess der et termoplastisk filament blir gradvis deponert, lag for lag. Det er denne prosessen som gir de endelige modellene sitt «stripete» utseende. Denne metoden gir mulighet for avanserte former og geometri. Prosessen kan sammenlignes med å bygge med Lego klosser, der hvert lag man printer er en Lego kloss som man fester sammen for å bygge oppover i modellen.

3D-utskriftsprosessen gjør et helt objekt til tusenvis av bittesmå små skiver, og gjør det deretter nedenfra og opp, skive for skive. De små lagene henger sammen for å danne et solid objekt. Hvert lag kan være veldig komplekst. Noe som betyr at 3D -printing kan lage bevegelige deler som hengsler og hjul som en del av det samme objektet. Du kan skrive ut en hel sykkel – styr, sadel, ramme, hjul, bremser, pedaler og kjede – ferdig montert uten bruk av verktøy. Det er bare et spørsmål om å ha riktige hull på riktig sted.

Andre materialer kan tilsettes til plast filament for å gi den ønskede egenskaper, for eksempel carbon fiber (karbonfiber), trefiber, jern, grafen, kobber, aluminium eller keramikkpulver. Med riktig utvalg av materialet kan man oppnå alt fra antistatisk til konduktivitet eller bare en tøff utseende.

Muligheter og begrensninger med 3D printing

Muligheter

Har du noen gang ødelagt noe, bare for å finne ut at det ikke lenger selges. Samt at du ikke kan erstatte det? 3D -printing betyr at du relativt enkelt kan skrive ut en ny. Det gir også muligheten for gjenstander som er skreddersydd etter dine behov. I framtiden vil det bety at møbler tilpasset hjemmet ditt, sko som er tilpasset føttene dine, måltider som skrives ut etter din smak med et tastetrykk. Selv medisiner, bein, organer og hud laget for å behandle skadene dine.

Begrensninger med 3D printing

Selv om 3D printing åpner mange muligheter, så er ikke det en perfekt løsning for alle problemer. 3D-printing er en fantastisk måte å produsere prototyper for å ta på og teste funksjoner, uten å måte sette opp produksjon i en fabrikk. For masseproduksjon og produksjon av store gjenstander er de mest konvensjonelle metodene fortsatt bedre egnet.

Lokale muligheter – Sotra

Profesjonelle 3D-Tjenester

STA Solution AS tilbyr alt innen 3D-Tjenester til det Norske markedet. Fra starten med en ide, til design, prototyper og endelig produkt. Ta kontakt med oss i dag for ett uforpliktende tilbud og prat om hva vi kan tilby din bedrift.

Les om vårt tilbud innen 3D-tjenester her.

Enten om ditt produkt må tåle en støt, være elastisk, nedbrytbart, antistatisk eller vannløselig så har vi løsningen til deg.